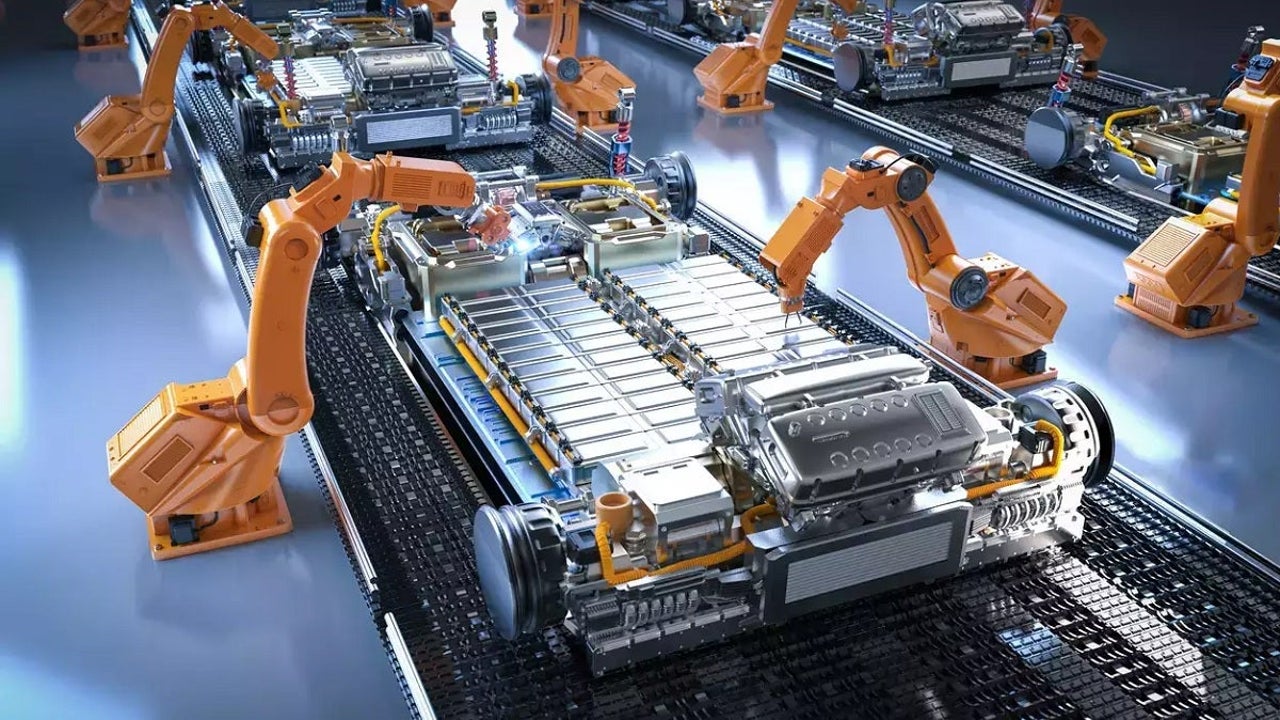

Chinese Researchers Achieve 99.99% Lithium Recovery in Battery Recycling Breakthrough

Chinese researchers have developed a battery recycling process that recovers over 99% of lithium and other key materials, promising improved sustainability for electric vehicle production

- March 26, 2025

- Updated: March 26, 2025 at 11:53 AM

Chinese researchers have announced a groundbreaking advancement in battery recycling, claiming to have developed a process that can recover an impressive 99.99% of lithium, along with 97% of nickel, 92% of cobalt, and 91% of manganese from used electric vehicle (EV) batteries.

The process, termed “neutral leaching,” employs glycine—a simple and stable amino acid—promising both safety and a significant reduction in environmental impact by eliminating harsh chemicals traditionally used in recycling methods.

According to a study published in the German academic journal Angewandte Chemie, this innovative method can separate materials in a mere 15 minutes during laboratory tests.

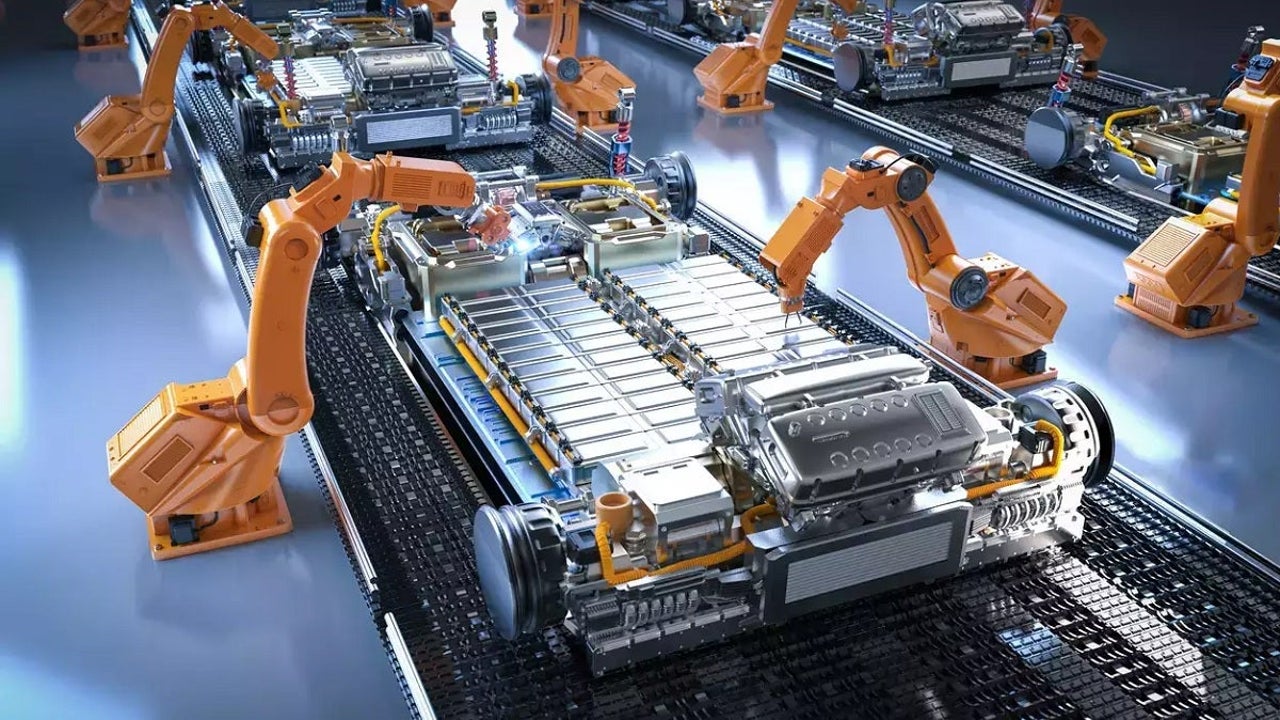

Major manufacturers have recognized the necessity of enhancing recycling capabilities

While this efficiency marks a significant step forward in battery recycling, experts caution that laboratory success does not always translate to commercial viability, leaving questions about scalability.

This development comes at a crucial time as the automotive industry increasingly focuses on sustainability, particularly given the rising costs and environmental damages associated with mining raw materials for new batteries.

Major manufacturers, including Toyota, BMW, Ford, and the Volkswagen Group, have recognized the necessity of enhancing recycling capabilities. Toyota, for example, has partnered with Redwood Materials, a firm founded by former Tesla CTO JB Straubel, to recycle materials from hybrid batteries like the Prius for future electric models.

Despite these collaborative efforts, the transition to a robust battery recycling market may take time. Reports suggest that while the interest in recycling is strong, the limited number of EVs and hybrids currently on the roads could delay the availability of sufficient recyclable materials.

Some analysts predict that the market for recycled materials won’t gain substantial traction until around 2030, indicating a potential bottleneck as the industry grapples with these evolving challenges.

You may also like

Berserk, the legendary manga by Kentaro Miura, arrives in Diablo 4

Read more

AI will dominate cybersecurity in 2025

Read more

The remaster of Oblivion arrives with controversy over its price

Read more

Tesla Plans Affordable Electric Vehicle Priced Around $25,000

Read more

YouTube is preparing a redesign for its TV app: Coming soon and here’s what we know

Read more

Bella Ramsey claims that she has had to train very hard for the second season of The Last of Us

Read more